About Us

Our Story

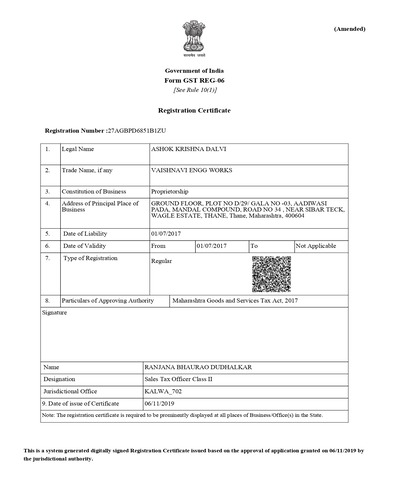

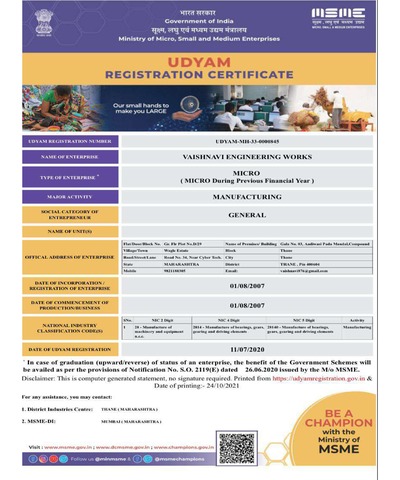

Vaishnavi Engineering Works is a leading engineering company specializing in the manufacturing of high-precision mechanical parts used in various machines. Established in 2007 by Mr. Dalvi and now managed by his son, Mr. Kedar Dalvi, the company is committed to delivering customized components tailored to client specifications. Located in Adiwasi Pada, Mandal Compound, near Cyber Tech Company, Thane (400604), Vaishnavi Engineering Works operates with all necessary certifications, ensuring quality and compliance with industry standards.

The company boasts a range of high-grade machinery and a skilled workforce dedicated to producing top-quality products. Its core expertise lies in CNC machining, fabrication, tool and die manufacturing, and the precise assembly of small mechanical components. The facility is equipped with advanced machines, including CNC machines, multiple drill machines with capacities ranging from 10-25, power presses with 15-ton and 30-ton capacities, tapping machines up to 6mm, hand presses, surface bench grinding machines with 0.1mm precision, a 4-foot lathe machine, and a 50-gram plastic molding machine.

With a strong focus on innovation, precision, and efficiency, Vaishnavi Engineering Works continues to serve diverse industries, providing reliable engineering solutions and maintaining its reputation for excellence in mechanical part manufacturing.

What We Offer

Our Authorized Certificates

We are a authorized engineering company with exceptional skills and craftmanship.